New Solutions Enhancing Efficiency in Machine Manufacturing

drilling, and end-preparation in a single cycle saves significant time, particularly in chassis and body production. Similarly, fast tool-changing systems and advanced angle measurement technologies in press brakes accelerate transitions between parts and strengthen production continuity.

Modern sawing machines used in cutting operations deliver more standardized and long-lasting performance thanks to servo-controlled feeding systems and automatic clamping solutions. In pressing operations, servo presses and intelligent tonnage management extend die life while reducing cycle times, thus increasing overall production capacity.

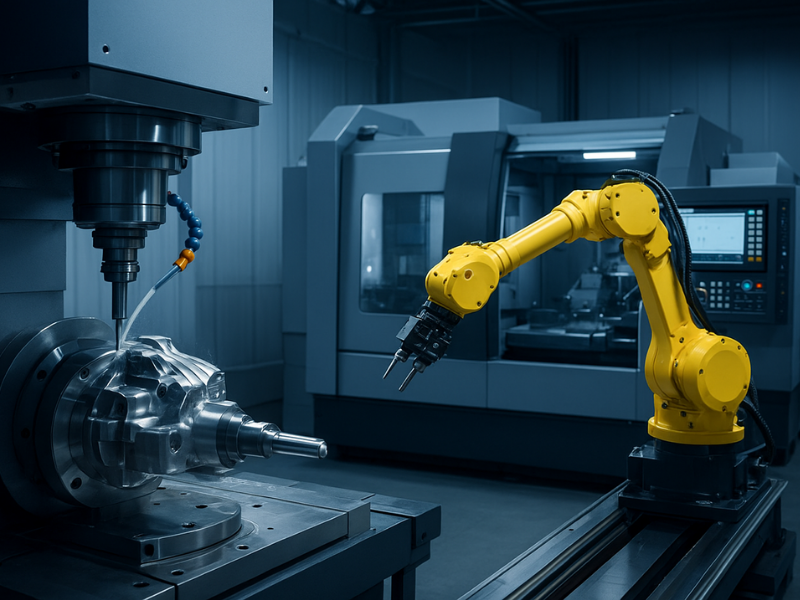

The most critical element complementing these machine technologies is robotics and automation. Robots take over tasks such as loading, unloading, stacking, welding, and precision handling, improving both workplace safety and production standardization. Thanks to automation software, machines communicate with each other, data is monitored in real time, and potential downtimes can be predicted in advance.

In conclusion, efficiency in machine manufacturing does not rely on a single machine but on an integrated ecosystem of technologies—ranging from laser cutting and press brakes to sawing, pressing, and robotic automation. This integration reduces costs while providing manufacturers with stronger competitiveness in the market.